Secondary Battery Machine Vision

Secondary Battery Machine Vision

-

INTRODUCTION

-

With the advent of Industry 4.0, the importance of Machine Vision has grown even larger. The role of Machine Vision has become more crucial, and its applications have expanded with the integration of AI-based technologies such as deep learning. This refers to giving machines the visual and judgment capabilities that humans possess. It is also a system that quickly and precisely replaces tasks that humans visually confirm and judge through a system composed of cameras, optical components, software, and so on. According to the Automated Imaging Association (AIA), Machine Vision encompasses all industrial and non-industrial applications consisting of hardware and software combinations that provide operational instructions for devices executing the functions of capturing and processing images.

Machine Vision is one of the foundational technologies in industrial automation. Machine Vision technology provides the capability to verify tasks performed by industrial equipment and make rapid decisions based on the verified information. The most common applications of machine vision are visual inspection and defect detection, locating and measuring parts, product identification, alignment, and tracking. Machine Vision has enabled improvements in product quality, increased production speeds, and optimized manufacturing and logistics processes over several decades.

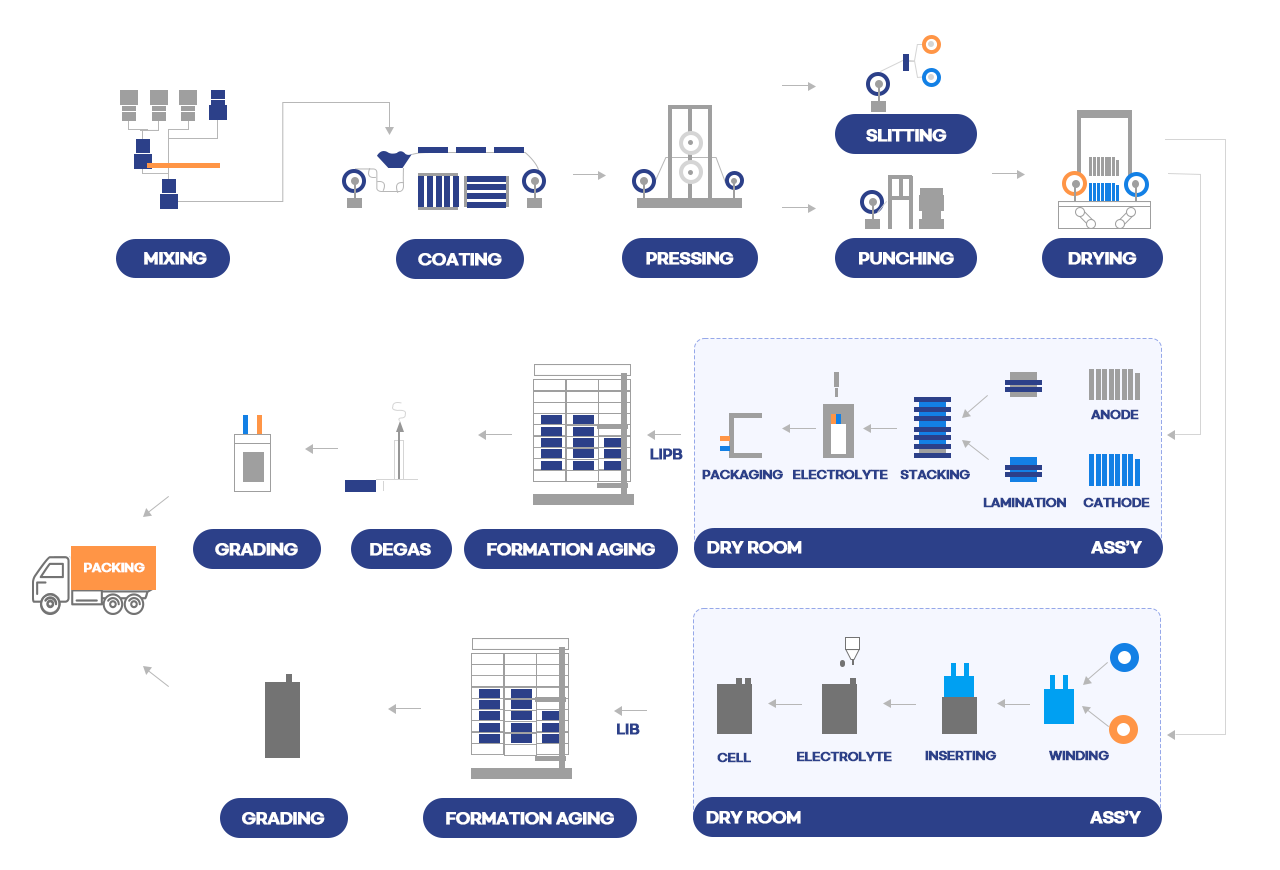

IVW Co., Ltd. supplies Machine Vision inspection systems optimized for the electrode process, assembly process, packaging process, and module process in secondary battery manufacturing.